Midwest Composite Technologies 3D prints parts to help companies develop new products.

Midwest Composite Technologies 3D prints parts to help companies develop new products.Exists a good chance in a few years to ride a motorcycle, buy a home appliance, or fly in an airplane with components that Midwest Composite Technologies LLC is helping to design right now.

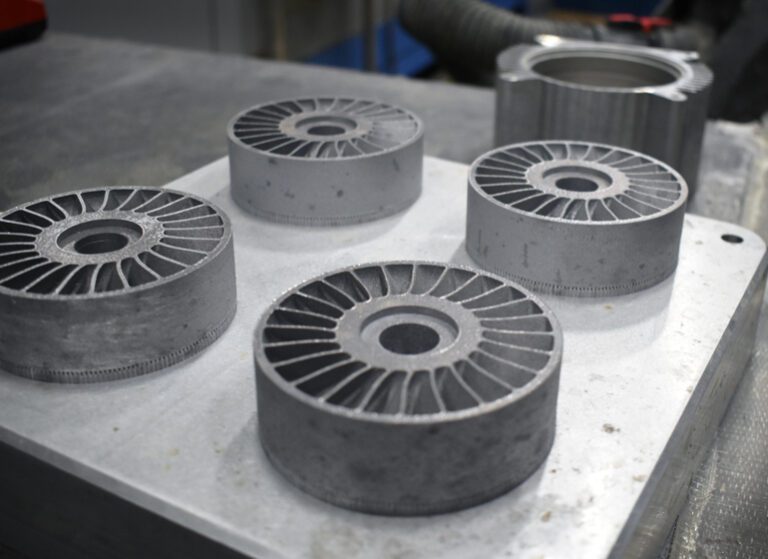

The Hartland-based company specializes in helping companies with new product development and low-volume manufacturing. It has been this way since Helmut Keidl started the company in 1984. Over the past 10 to 15 years, MCT has increasingly focused on the use of additive manufacturing or 3D printing.

Core Industrial Partners, a Chicago-based private equity firm, acquired Midwest Composite Technologies last year. Ryan Martin, a former GE Additive executive, joined MCT earlier this year as managing director.

Martin said the company has the benefit of decades of experience developed by the Keidl family, and Core Industrial Partners is providing additional capital to continue investing in growing the business. He added that additive manufacturing opens up new design and engineering possibilities.

“In traditional manufacturing, the more complicated you make a part the more expensive it is,” Martin said. “Plus, sophistication in many of these places can be obtained for free.”

He pointed out that the most expensive thing to print with any material is a solid block. Designing complex parts with the goal of using less material actually reduces the cost of printing each part. Since 3D printing creates things one layer at a time, parts can be designed differently.

“You have incredible design freedom,” Martin said. “That ability to think very organically and non-traditionally allows people to come up with some very unique concepts… you can create things that rotate around parts, you can make curves, you can make circular, you can have cryogenic chambers just built into the parts . “

He said major manufacturers increasingly understand how to design things for additive manufacturing, although there are limitations to the technology.

“If you just take a traditionally manufactured part and then additively manufacture it, there's no value in that,” he said. “Where there's a lot of value is when you look at the place and completely redesign it.”

Midwest Composite Technologies works with Fortune 500 companies and their suppliers, primarily in the medical device, agriculture, transportation, aerospace and general consumer industries, Martin said. About 70% of the work is focused on prototyping, while the remaining 30% is low-volume production.

In many cases, MCT works with companies on components and parts of their products, making them lighter or stronger, integrating components or improving them.

“Where we really help them is in rapid iterations,” Martin said, noting that a company can go from a computer-aided design file to a completed prototype in hours or days because of 3D printing. “They can send us a file this afternoon, we can make it overnight or during the day sometimes, send it to them and have it in their office.”

Speed is a plus for MCT. Martin said the company recently had a medical device customer develop a new product, and long lead times for a metal casting part were delaying development. Instead of waiting, MCT was able to print 25 of the parts and allow the customer to build demo models.

Midwest Composite Technologies has 45 additive manufacturing machines with capabilities in both metals and plastics. The company, however, is focused on more than additive manufacturing. Martin said MCT also does CNC machining, injection molding, fiberglass component manufacturing, mold and tool manufacturing, finishing and painting.

“Usually the people who come to us are engineers,” Martin said. “It's their design, it's their product, and so from our side, one area we've invested heavily in is our sales engineers.”

He said the company tries to work with OEMs to understand what a prototype is intended for and what challenge the customer wants to solve. Sometimes a part is for testing, other times it is for demonstration. The challenge could be to reduce delivery time or cost, or possibly change material. From there, the availability of a variety of manufacturing methods gives MCT options, Martin said.

“If you're an OEM, that's one reason you come to us,” he said.

Midwest Composite Technologies LLC

1050 Walnut Ridge Drive, Hartland

INDUSTRY: Additive manufacturing/prototyping

EMPLOYEES: 65